Overview

MT 40 is manufactured utilizing our new state-of-the-art process that produces pipe that exceeds strict industry standards and easily outperforms Schedule 40 pipe in both strength and corrosion resistance and in-line galvanized pipe in salt spray tests.

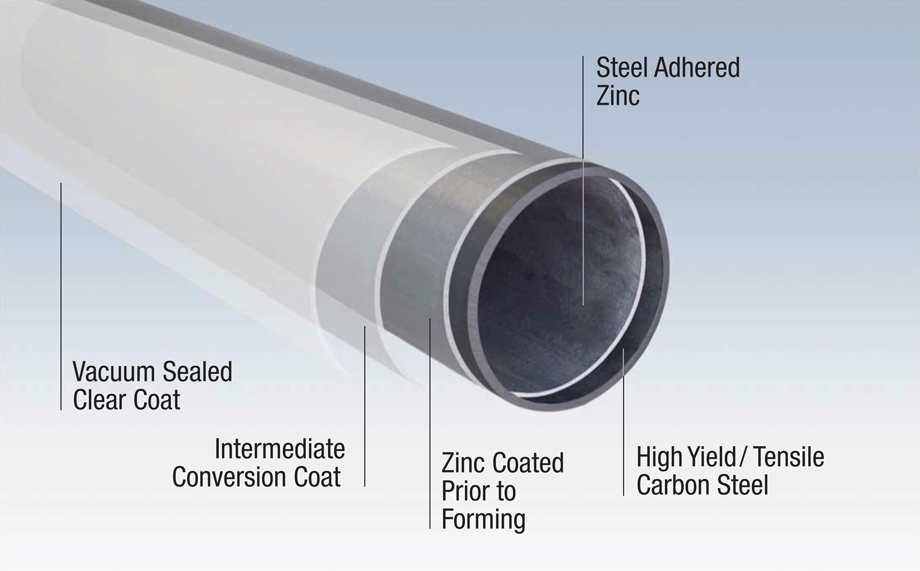

Manufacturing Process – MT 40 is manufactured using hot rolled steel. A triple layer of OD corrosion protection consisting of a steel-adhered zinc bath, an intermediate conversion coat and a clear vacuum sealed top coat is then added to provide the maximum in protection and durability. The ID is zinc coated prior to forming.

High Yield Strength 50,000 PSI Steel – and triple coat protection results in pipe that is lighter and outperforms Schedule 40 in strength and corrosion resistance.This unique process means that MT 40 is 37% stronger and 21% lighter than Schedule 40 tubing.

Specifications

F-162 Federal Aviation

M-181 AASHTO

UFGS 02821 (supercedes CEGS 02821)

NFGS 02831 Dept. of the Navy

RR F-191 Chain Link Fence Specification

ASTM A513

ASTM A500 Grade B

50,000 Yield

ASTM F-1043 Group IC, IC-L

Made in U.S.A. – All MT 40 product from Midwest Tube Mills is manufactured in the USA and is in compliance with federal, state and local specifications. We meet Buy America(n) requirements.

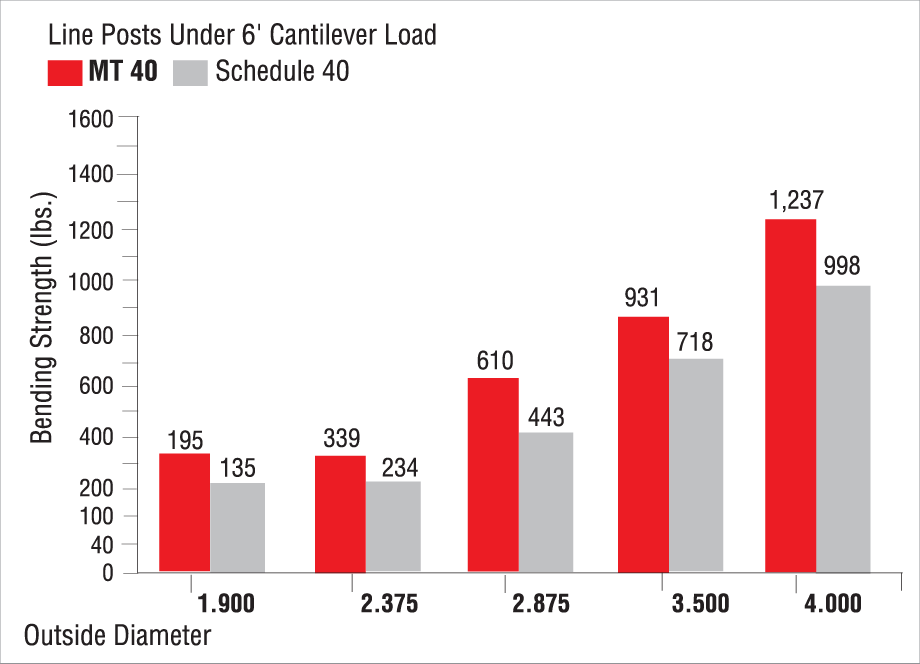

MT 40 vs. Schedule 40

Strength Comparison

Diagram